30 September 2016 – Mellon Sawyer Seminar Hands On Session

30 September 2016 – Mellon Sawyer Seminar Hands On Session

Mellon Sawyer Seminar participants met at the Oakdale Papermaking Facility near Iowa City on a beautiful autumn day to get hands on experience with manuscript and book technologies and production techniques. The workshop included scroll and codex structures, Nepalese and beaten bark papers, Japanese papermaking, western papermaking, parchment making, writing surfaces, tools and inks, and was led by professors and graduate students from the University of Iowa’s Center for the Book.

Book Structures

Book Structures

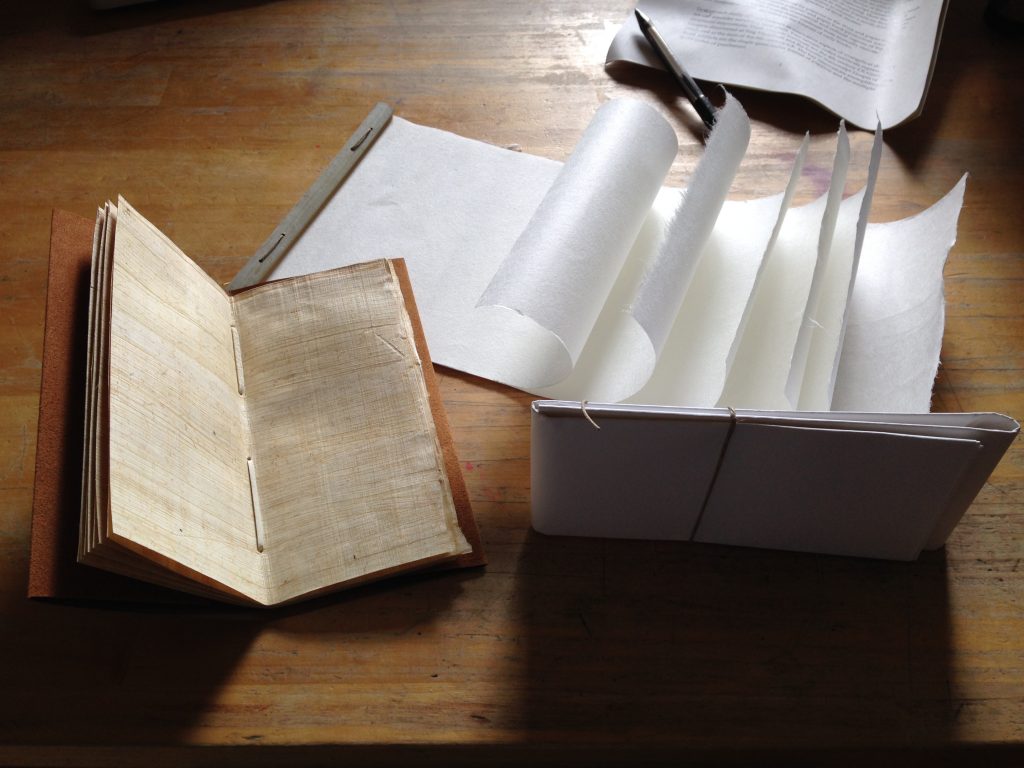

Book Conservator Gary Frost and Elise Hochhalter of the UICB demonstrated how to produce 3 book structures: a north African Nag Hammadi style tacket binding with a papyrus textblock, a Chinese ‘whirlwind’ book like those found in the book repositories of the caves of Dunhuang, China, and a folded pocketbook based on papyrus exemplars from dynastic Egypt.

The Coexistence of Scroll and Codex in the Classical West

The surviving evidence suggest that the codex [book bound on one edge] became the dominant carrier of textual information in western Europe by the 4th century [see the Leuven Database of Ancient Books and William Johnson’s lecture]. But both Gary Frost and Paul Dilley [in his “Roll to Codex?” lecture] emphasize that the roll/scroll and codex were in concurrent use for centuries before and after this date [btw, philologists prefer the term ‘roll’ over ‘scroll’, but they are interchangeable – I’m sure there’s a story there!]. Our idea of what early book use looked like – in the classical west at least – is heavily influenced by the form that came to dominate, the codex [i.e., the scroll was prevalent for longer that surviving evidence suggests]. The idea of the inevitable dominance of the codex may be colored by the underlying narrative of Christian triumphalism put forth by early Christian writers – the idea that the codex gained dominance over the pagan/classical scroll form because it held the word of God. It was meant to be. Instead, the codex may just have been a better survivor in those transitional centuries – physically speaking – and the numbers of surviving codex vs. scroll exemplars may present a skewed view of what was happening on the ground in the classical west. Frost noted that ‘a resulting survival disparity between the two formats skews our perspective of interaction and obscures their actual interdependent presences and functionalities at the time of their initial use.’ Continuity and co-existence of scroll and codex must be stressed. It was not a clash of formats, but a co-mingling, until the two forms gradually found their way into common use for certain texts – based on religious, cultural or literary custom.

Scroll or Codex – a Choice

When and why the scroll form was maintained in association with certain texts is a regular topic of discussion in the Seminar. Certain texts within certain cultural and religious traditions continued to be produced in scroll form long after the codex came to dominate. Sometimes this had to do with the sacred quality of a text – such as the Torah – and the religious customs of copying, storing and reading such a text within the Judaic tradition. Tradition also played a role in the use of scroll [over codex] for ‘published’ literary works in the Graeco-Roman world. It was just what one did with one’s finished work of literature. Custom here looked back to the great traditions of the past – a nod to the writers and orators who came before. In some cases, the choice of which form a text would take [scroll or codex] was decided based on the historical moment in which a certain text moved out of the oral tradition and into the written one.

Scroll to Codex Technology Transfer

So, why did people eventually move from scroll to codex as the carrier of textual information in the west? Frost emphasizes book commodity as a driving factor in this shift. The codex was more portable, easier to store [rectilinear and compact], its texts more accessible for reading and cross-referencing, than the scroll [though an argument can be made that cross-referencing was only one of many ways to use a text, and was not a driving factor if you’ve memorized a literary text]. Early users may also have noted that the codex preserved writing better. The codex sheet material was stored flat and remained flat when the book was opened and closed [so the writing surfaces did not rub together]. The scroll, which was rolled and unrolled was more likely to damage pigments and inks during use.

Thinking a bit past the ‘why’ question – we might ask how did this scroll to codex shift take place? The technology writing and sheet production (papyrus or parchment in the west) were already well-established. And when you see the scroll unfurled [as Frost does, above] with narrow columns of text running perpendicular to the length of the roll, it’s not a great leap to image folding it up, rather than rolling it. This was certainly something that happened in the Asian tradition, where the accordion style book was developed by folding the scroll perpendicular to its long width [and folding was also a way to store scrolls]. Other forms of folding long sheets took place long before this. In dynastic Egypt (thousands of years before the advent of the codex in the west, and before the accordion in the east) long papyrus sheets were folded along the length and then folded down into a compact packet for easy transportation [similar to the way birch bark manuscripts of northern Indian subcontinent have been found, rolled and folded – though these were ritualistic and religious in nature, and not meant to be transported and read later].

The Relationship of Book Format to Materials

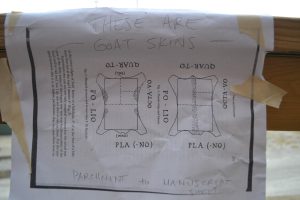

It is also important to remember that book size and format has everything to do with the dimensional constraints of the materials originally used to construct that book. A folio size manuscript is dimensionally equal to the size of one trimmed and folded parchment goat skin. The Nag Hammadi codices [4th-c. Coptic gospel books], tall and thin by later book standards, related dimensionally to the papyrus that was available at the time and in that place [Egypt]. Similarly, early printed book formats in the west [15th and 16th c.] took their dimensions from standard papermaking mould sizes in use at the time. Format – here, in terms of dimension – originates with the particularities of materials.

Nepalese Papermaking

Participants successfully made several sheets of paper while at the Mellon Sawyer workshop, including Nepalese paper which is made from raw Lokta fiber, the light inner bark of the Daphne bhoula, Daphne papyracea and other trees. We got a hold of some of Lokta fiber from Jim Canary, Book Conservator at Indiana University (thanks Jim!) and UICB MFA student Lisa Miles guided us through the end stages of the production process [post-cooking and rinsing]. Lokta fiber is cooked, rinsed and beaten very briefly [about 5 mins.] with a large wooden mallet, and picked clean of undesirable flecks of dark bark.

The beaten fiber is then mixed vigorously in water to form a slurry that is poured into a mould floating in a pool of water. A stick or hand can be used to evenly distribute the fiber throughout the mould. The mould is then pulled up from the vat, water drained and mould stacked in the sun to dry. This is an ancient, low-tech, method of making paper, traditionally done by husband and wife teams. Tim Barrett believes it was originally in use in China, c. 100 BC.

I was struck by the low tech nature of this production – still done today in Nepal as it was thousands of years ago, with minimal beating time and the floating mould technique for sheet formation. Papermaking later developed independently in China, Korea and Japan, each tradition moving to a method that used a single mould, with fresh paper transferred to a stack of wet sheets. This allowed the mould to be reused immediately to pull more sheets (rather than the Nepalese technique where each sheet stays on the mould until dry). This later method (which reused mould and transfered wet sheets to a stack) required more training and a lengthy apprenticeship to master, but produced a finer sheet more suitable for writing and artistic and textual production.

This opens up questions about the availability of unskilled domestic labor – domestic partners (and women and children) are always more abundant than a specialized labor force, which you’d have to select and train in a rigorous years-long apprentice system. Did low tech technologies spread more rapidly through premodern Asia than more skill-dependent ones? As long as you had water, wood, cloth, and a source for fiber, the floating mould style of production was low tech and relatively straightforward. In theory, it was a technology that could be transferred to anyone and any place with water and a source of fiber and wood (to build frames, cook fiber). Though easily transferable as a technology, the downside to production was that paper on the moulds had to dry and be peeled off before the mould could be used again. The floating mould style required space, sunshine and many moulds. Was it a more stationary technology because of this or did it spread easily because of its low tech investment? Interestingly, Arab papermaking in North India uses a floating mold technique, though sheets are dried by brushing them out on a plaster wall in the sun.

Lisa Miles also showed us some examples of Mesoamerican bark paper that she had collected from her recent travels. Bark paper is not paper in the proper sense, but the inner bark of trees laid in strips and beaten to form a uniform sheet material. Barrett and Miles suggest these methods are close to those still practiced in Indonesia today. To their knowledge, the earliest dated Indonesian bark paper dates to the 14th century, but the technique is older and may have had a significant role in the early transmission of Eurasian manuscripts.

Lisa Miles also showed us some examples of Mesoamerican bark paper that she had collected from her recent travels. Bark paper is not paper in the proper sense, but the inner bark of trees laid in strips and beaten to form a uniform sheet material. Barrett and Miles suggest these methods are close to those still practiced in Indonesia today. To their knowledge, the earliest dated Indonesian bark paper dates to the 14th century, but the technique is older and may have had a significant role in the early transmission of Eurasian manuscripts.

Japanese Papermaking

Japanese Papermaking

UICB MFA student Johan Solberg patiently shepherded participants through the process of making Japanese paper. Japanese fiber comes from the inner bark of trees (such as Mulberry), which is steamed, stripped, cooked and beaten with wooden mallets for extended periods of time. The beaten fiber is then mixed in deep vats of water with a viscous formation aid (made from Tororo-Aoi root) and ‘pulled’ with a sugeta – a handsewn bamboo screen (su) and frame (keta). Participants noted how much rhythm and dexterity was required to successfully pull Japanese sheets (sometimes in moans and grunts)! This is difficult work, and requires much practice, trial and error to master.

Another difference between the floating mould and later papermaking techniques is the use of a formation aid – Nepalese/floating mould method using none (just fiber and water) and Japanese using the viscous liquid produced from the root of the Tororo-Aoi plant. The liquid, mixed with fiber and water, prevents the water from draining too quickly from the mould and allows the fiber to spread evenly across the sugeta to form a well-distributed sheet suitable for writing. Participants took a walk at noon to visit the Mulberry bushes and Tororo-Aoi plants used for production of Japanese Kozo paper at Oakdale. The Mulberry is harvested each year the week of Thanksgiving (mark your calendars-need all hands on deck!) in order to prep fiber for winter, the traditional time for Japanese paper production.

Western Papermaking

Participants also got their hands wet making western style paper. The process differs from Asian papermaking in its use of a mould with a screen and different types of fiber – such as flax, cotton, hemp. It also uses wool felts as interleaving between sheets of paper, which allows them to be pressed before drying. The team at Oakdale Papermaking Facility has made fantastic strides in understanding historic paper production techniques by replicating a day in the life of a late medieval papermaker. Here is a video of their marathon-style experiments in trying to replicate the production of 2,000 sheets a day of chancery paper. This first marathon session did not produce this goal, but much was learned in the process – and it inspired a repeat performance [summer 2016] which was successful. Whew. Note: keep all those old linen tablecloths from your Grandma – those make great paper!

Parchment Making

The back deck was the site of parchment production, using medieval tools [mostly] and two goat skins. The skins had already been de-haired and de-fleshed by parchment-maker extraordinaire Jesse Meyer, of Pergamena in upstate New York [thanks Jesse!]. Jesse’s family has been making leather for almost 500 years, and he now makes parchment as well. Jesse was helpful in advising me and book conservation lab technician Bill Voss on how to get the job done. I made the wooden stretching frames and Bill fashioned a scraping lunarium from a circular saw blade and copper tubing covered with leather – and it worked! Skins were stretched on the frame, tears mended, skin stretched, dried and sanded to produce a product suitable for writing. Simple process, but like all things – easy to do, hard to do well.

Parchment overtook papyrus as dominant sheet material for codices in the 5th century – perhaps because it was better suited for the newly dominant book form, the codex, which required folding [instead of rolling, like a scroll/roll].

Parchment overtook papyrus as dominant sheet material for codices in the 5th century – perhaps because it was better suited for the newly dominant book form, the codex, which required folding [instead of rolling, like a scroll/roll].

It was overwhelming to think of the vast numbers of animals it took to produce one book. For a large [folio size] liturgical manuscript, for example, each folded sheet was made from the skin of one animal [goat, calf, sheep]. It is easy to see how the parchment-making industry went hand in hand with animal husbandry and the slaughter of animals for meat – every part was used. It was also striking to think of the work and cost involved in producing one sheet of parchment vs. one sheet of western paper. Paper had been used in Italy (e.g., the papal chancery) for centuries before paper mills and the craft of papermaking arrived in the 13th century. However, parchment was king until the advent of the printing press in the mid-15th century. Printing on parchment was difficult – and with the number of books that were being produced, it became impossible [in terms of animals, labor, time] to fill the printer’s growing demand for sheet material. Paper was likely ten times cheaper than parchment, easier to print on – and as the Atlas of Early Printing shows, paper could be produced much more quickly to meet the demands of presses popping up all over Europe. Printing was the catalyst for the wide-spread adoption of paper as the dominant sheet material in western Europe. This type of shift in use of materials and the material connections to texts is of central interest to the Seminar.

Calligraphy and Scribal Practice

UICB calligraphy professor Cheryl Jacobsen gave participants a brief intro to Scriptorium 101. How were texts produced with quill, nib, bamboo, reed and brush? What inks and sheet materials were used – and how do tools and materials relate to the texts they hold? With her expert eye and knowledge of the hand’s relationship to pen stroke and sheet, she broke down some basic letters and how they are constructed on the page. This was illuminating for participants, who came away with a reverence for medieval scribes – the good ones and even the bad ones! It took thousands of hours of practice on hundreds of texts to produce an accomplished scribe – an equation that hasn’t changed in 1,500 years. The knowledge of how penstrokes are made and the order and number of penstrokes is helpful for paleographers and those studying ancient scripts and ‘hands’ [the handwriting of an individual scribe]. For example in a Gothic script like littera textualis, the number of penstrokes to make an ‘e’ for example, can vary depending on whether the scribe is copying out a formal treatise [4 penstrokes] or a quickly copied text in a simplified littera textualis [2 penstrokes]. Training the hand can inform the eye.

Conclusions from the Workshop

The transformation of raw materials into text-ready manuscript sheets felt miraculous. As much as one can understand intellectually how manuscripts were produced in the Middle Ages – the direct interaction with materials is illuminating. It both de-mystifies the process [because at a basic level, it’s simple] and leaves one in awe of the labor, materials, and skill that were required to produce medieval texts. We took one step closer to the experience of the medieval craftsperson and an understanding of the material aspects of the texts we study as historians, philologists, scientists, and digital humanists.

Melissa Moreton [UI Mellon Sawyer Postdoctoral Fellow]